Zhucheng Luxin Yida Machinery Technology Co., Ltd

Service telephone 15762524111

Service telephone 15762524111

-

Service telephone

15762524111

Equipment introduction:

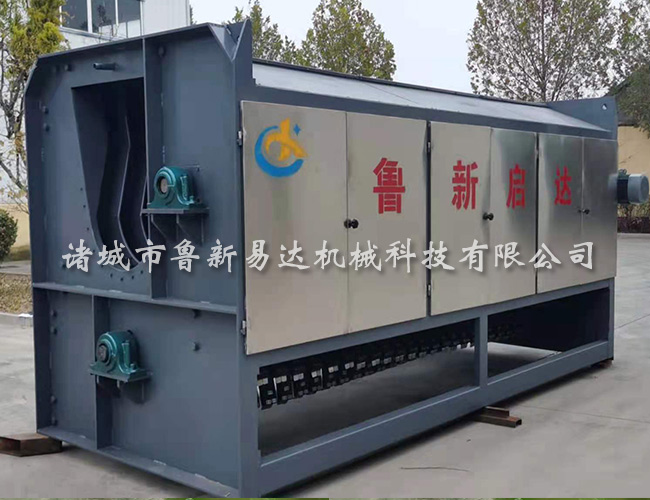

Screw roughing machine (also known as screw planer, screw unhairing machine, etc.) is used in large and medium-sized pig slaughterhouses. A total of two sets, a positive and a negative continuous hair. The screw roughing machine is made of national standard material, stainless steel shell and 10 mm thick hot-dip galvanized angle steel frame. High roughing rate and high speed.

The pig out and pig in parts can use chute or grader. Design and select according to the size of the customer's workshop.

Slaughtering line process:

1. Pig dehairing machine is a kind of equipment for pig dehairing and scraping after slaughtering. The equipment is divided into 200300400 models. According to the customer's demand, our company also produces a small model of 200 model, which is suitable for small slaughtering and processing plants with slaughtering capacity less than 50 heads per day and pig weight less than 500 kg. After finishing slaughtering, pigs should enter the special pig soaking pool for soaking.

2. Pig scalding pool is divided into iron and stainless steel, stainless steel is more durable than iron. The scalding pool is equipped with a temperature sensor, and the distribution box is equipped with a temperature controller, which can keep the temperature within the temperature range you set. It changes the traditional way that the pig can only rely on the touch to test the temperature, so as to prevent the pig from aging or insufficient immersion. For domestic white pigs, our guidance temperature is 60-65, and the water temperature is 3 minutes. The water temperature and scalding time should be changed according to different pig breeds and local actual climate and temperature.

3. After the pig is soaked and ironed, use the control lever of the pig unhairing machine, and use the hydraulic rake to pick up the pig from the ironing pool. If the roughing roller has not started to operate, it is recommended to put the pig back to the cavity of the roughing machine, so as to prevent the pig leg from entering the gap of the roughing block and blocking the pig leg, so as not to break the pig leg. The hydraulic rake can lift 4 tons of oil well with long service life and good effect.

4. When the pig is on the rake, start the operation button of the roughing roller, and the lever controls the rake to continue to lift. The pig rolls into the machine cavity for rapid unhairing. The roughing time is generally 15 seconds, and the net wool rate is 98. The effect is really good. There is a big red emergency stop button on the distribution box. In case of emergency, such as pig leg sticking, the button will automatically rise after the problem is solved, Get back to work.

5. After the pig hair removal, the work of pig hair beater is completed. Pigs need to be cleaned in the cleaning tank, and then go to the next stage of cleaning, inspection, splitting and other processes, so that the slaughtering process can be completed.

Equipment features:

1. The spiral propulsion mode is adopted to realize the automatic forward movement and automatic pig delivery of pig carcass in the process of planing, so as to save manpower and improve production efficiency;

2. The continuous and orderly operation mode ensures that each pig carcass goes in and out first in the unhairing process, and will not be misplaced, so as to ensure the accurate quarantine and the establishment of product traceability system;

3. Two horizontal soft blade rollers are used in the shaving engine room, and the rollers are equipped with rubber shaving knives;

4. The drum knives are scattered in the U-shaped fence, and the pig carcasses are entrusted to the fence after entering the machine, which can effectively solve the problem of destroying the pig carcasses due to the immobility of the carcasses;

5. There is a water spray pipe on the top of the machine, which can spray the pig body in the process of planing to improve the efficiency of Unhairing;

6. The machine adopts the power device of motor direct connection reducer, which avoids the maintenance failure rate and the pollution of lubricating oil caused by chain and sprocket transmission;

7. The machine is equipped with pneumatic pig gate, which can be manually controlled according to the unhairing effect, so as to extend the unhairing time and improve the unhairing rate;

8. The machine is used in series.

-

About us

Introduce Product News -

Quick links

leave word Sitemap manage -

contact

linkman:Mr gao phone:15762524111 address:hucheng Shiqiao Town Industrial Park -

ZHUCHENG LUXIN YIDA MACHINERY TECHNOLOGY CO., LTD

Copyright © ZHUCHENG LUXIN YIDA MACHINERY TECHNOLOGY CO., LTD All rights reserved